When most of us think of modular buildings, we picture those trailer-like structures on construction sites – the ones with panel walls and the electrical wire that dangles outside. Modern modular buildings are a far cry from those flimsy seventies-era trailers.

Modern modular buildings are marvels of technology and engineering. To learn more, Healthcare IT Today went to visit Fero International, a company that fabricates advanced modular buildings for the healthcare, education and municipal markets. We sat down with Fero’s CEO, Sabrina Fiorellino to learn more.

Modular Buildings for Healthcare

For healthcare providers, Fero can build modular buildings that contain:

- Inpatient rooms

- Long-term care rooms

- ICUs (including negative pressure rooms)

- ORs

- Outpatient clinics

- Specialty services like dialysis unites, diagnostic imaging, rehabilitation, etc.

Fero builds these types of units in close collaboration with their customers so that when they arrive, they already have the HVAC, oxygen, suction, medical gas lines, wiring, and other needed infrastructure. Fero can even install equipment from the provider’s preferred vendor like exam tables, OR lights, large monitors, and wireless access points.

All that a provider has to do is get the foundation ready.

“A modular facility is the perfect solution for a hospital that is 5-10 years away from their new building,” said Fiorellino. “We can give them space in a very short time so that they can deal with their backlog NOW, in a fully functional building that can bridge them to their new facility…or become part of it.”

Modular Building is Significantly Faster

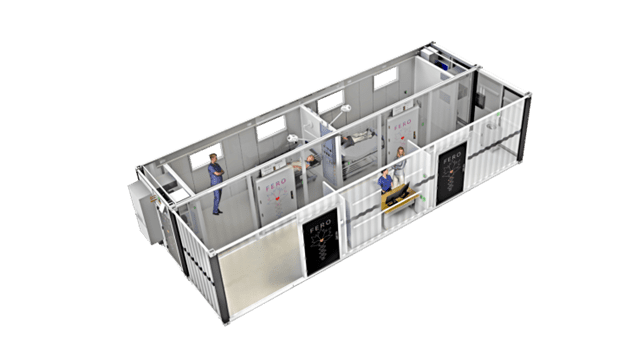

“We are a volumetric modular building company,” explained Fiorellino. “We do 90% of the construction in our facility, adhering to all the proper building codes. Then we ship the modular components to the site where they are assembled like Lego blocks.”

Since most of the construction happens indoors at the climate-controlled Fero facility, there are no lost days due to weather. As well, Fero has organized their fabrication process so that the building travels along an assembly line where each work station is optimized for the task. Because of this, Fero is able to contruct their buildings much faster than a traditional onsite builder.

How much faster? “We can build 30-50% faster,” stated Fiorellino. “That is significant, especially in today’s financial environment with high interest rates. If we can deliver 50% faster, that means a lot less carrying costs which means a much better ROI for our customer’s project.”

Modular Buildings are Higher Quality

Building indoors has several other advantages including:

- Less waste because raw materials are cut and milled with automation rather than by hand oniste

- Building materials are not exposed to the elements which can lead to issues down the road

- Better quality control which means fewer warranty claims

Watch the interview with Fiorellino to learn more about how modular construction should be a top option for healthcare providers who need more space or who need more than trailer to serve remote parts of their community.

Learn more about Fero International at: https://ferointl.com/

Listen and subscribe to the Healthcare IT Today Interviews Podcast to hear all the latest insights from experts in healthcare IT.

And for an exclusive look at our top stories, subscribe to our newsletter and YouTube.

Tell us what you think. Contact us here or on Twitter at @hcitoday. And if you’re interested in advertising with us, check out our various advertising packages and request our Media Kit.

Disclosure: Colin Hung advises MedEssist through ventureLAB, a non-profit Canadian innovation hub.

Get Fresh Healthcare & IT Stories Delivered Daily

Join thousands of your healthcare & HealthIT peers who subscribe to our daily newsletter.